Managers of 10 branches of the "My Business" center underwent training in lean technologies at the "Process Factory".

06 November 2025 17:55 Economy

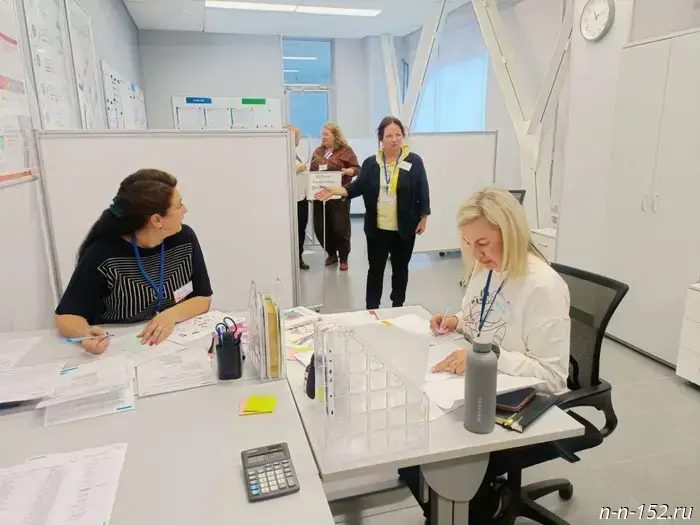

Ten representatives of municipal entrepreneurship support infrastructure were trained in lean technologies at the "Process Factory." The event was organized by the Regional Competence Center in accordance with the goals and objectives of the federal project "Labor Productivity" of the national project "Efficient and Competitive Economy."

The training was attended by heads of branches of the "My Business" center from the Shatkovsky, Chkalovsky, Pochinkovsky, Navashinsky, Bogorodsky, Urensky, Semenovsky, Bolsheboldinsky and Balakhninsky districts, as well as Zavolzhye.

According to the Minister of Industry, Trade and Entrepreneurship of Nizhny Novgorod Oblast, Maxim Cherkasov, "The 'Process Factory' is a training site equipped with special stands that allows personnel to be trained in lean production. Experts from the 'My Business' centers completed training under the 'Office Processes Factory' program."

"We are consistently developing the system for training and upgrading the qualifications of specialists at the 'My Business' centers. This makes it possible to continuously improve the quality of work and update knowledge about government support instruments. An additional training format for employees was the 'Process Factory', where participants became acquainted with lean technologies. Specialists mastered practical tools for increasing efficiency: principles of workspace organization, logistics optimization, and assessment and reduction of labor costs," said Maxim Cherkasov.

The Regional Competence Center of Nizhny Novgorod Oblast launched the "Office Processes Factory" program in 2022. Training participants include representatives of executive and municipal authorities, as well as enterprises participating in the federal "Labor Productivity" project. To date, 54 trainings have been held, with more than 500 people trained. In total, within the federal "Labor Productivity" project in the region, more than 5,000 people have mastered lean technologies.

"We didn’t just study theory, we gained real-time experience applying lean production tools. In the training we studied the systematic use of methods such as 5S*, standardization and mapping of flows related to document circulation. They allow not only to identify hidden losses but also to achieve significant improvements in key process performance indicators," shared a training participant, head of the "My Business" center of the Balakhninsky municipal district, Natalya Khodova.

In Nizhny Novgorod Oblast, the tools of the federal project "Labor Productivity" of the national project "Efficient and Competitive Economy" are being implemented by 301 regional companies.

To become a participant in the federal project "Labor Productivity," you must submit an application on the IT platform: производительность.рф. From 2019 to 2024 this support measure was implemented within the national project "Labor Productivity," and from 2025 it has been carried out within the federal project "Labor Productivity" of the national project "Efficient and Competitive Economy." Consultations on participation in the federal project can be obtained at the "My Business" center either in person or via the hotline: 8 (800) 301-29-94 (toll-free).

The national project "Efficient and Competitive Economy," initiated by Russian President Vladimir Putin, is the main tool for forming a new growth model. It includes federal projects aimed at developing small and medium-sized businesses, increasing labor productivity, boosting investment activity, low-carbon development, and developing the state system of statistics and forecasting.

*5S — a system for organizing and rationalizing the workspace, one of the lean production tools. It consists of five elements:

- sorting — clearly separating needed and unneeded items and getting rid of the latter;

- set in order — orderly and precise placement and storage of necessary items so they can be quickly found and used;

- shine — keeping things clean and tidy;

- standardization — the condition for performing the first three rules;

- sustain — cultivating the habit of strictly following established rules, procedures and technological operations.

NIA "Nizhny Novgorod" has a Telegram channel. Subscribe to stay informed about major events, exclusive materials and timely information. Copyright © 1999—2025 NIA "Nizhny Novgorod". When reprinting, a hyperlink to NIA "Nizhny Novgorod" is mandatory. This resource may contain 18+ materials.

Другие Новости Нижнего (Н-Н-152)

The driver of a foreign car rammed into six parked cars in Afonino.

Nizhny Novgorod News

The driver of a foreign car rammed into six parked cars in Afonino.

Nizhny Novgorod News

A residential building and garages may be demolished to make way for a parallel road to Lenin Avenue in Nizhny Novgorod.

Nizhny Novgorod News

A residential building and garages may be demolished to make way for a parallel road to Lenin Avenue in Nizhny Novgorod.

Nizhny Novgorod News

Nizhny Novgorod Oblast entered the top 10 of the all-Russian "Region-NKO" ranking.

Nizhny Novgorod News

Nizhny Novgorod Oblast entered the top 10 of the all-Russian "Region-NKO" ranking.

Nizhny Novgorod News

Andrey Sanosyan, as part of the AIRR delegation, visited China, where he presented the potential for cooperation with the Nizhny Novgorod Region.

Nizhny Novgorod News

Andrey Sanosyan, as part of the AIRR delegation, visited China, where he presented the potential for cooperation with the Nizhny Novgorod Region.

Nizhny Novgorod News

The State Duma proposed launching a government service to vet nannies.

Nizhny Novgorod News

The State Duma proposed launching a government service to vet nannies.

Nizhny Novgorod News

Evgeny Lyulin: "The development of agricultural classes helps provide the region with qualified personnel for the agro-industrial complex."

Nizhny Novgorod News

Evgeny Lyulin: "The development of agricultural classes helps provide the region with qualified personnel for the agro-industrial complex."

Nizhny Novgorod News

Managers of 10 branches of the "My Business" center underwent training in lean technologies at the "Process Factory".

Nizhny Novgorod News